Products

Products

Contact Us

BoZhong (Shandong) Industrial Equipment Co., Ltd. | Part of the Atlas Copco Group

Address: No.50# YiDa Road, NanDing Town, Economic Development Zone, ZiBo, ShanDong, China

Tel: +86-533-2530388

Website: en.zbbz.com

MVR evaporation system

Download the brochure of MVR series (pdf)

Summary:

MVR evaporator is the abbreviation of Mechanical Vapor Recompression. MVR re-uses the secondary steam energy produced by its own, thereby reducing the demand for external energy. Early in the 1960s, Germany and France have successfully applied this technology in chemical, pharmaceutical, paper, sewage treatment, seawater desalination and other industries. Its working process is compressing low temperature steam by the compressor, raising temperature and pressure, increasing enthalpy and entering into heat transfers for condensation, to make full use of steam latent heat. In addition to drive start, the whole evaporation process needs no steam.

In the multi-effect evaporation process, the secondary steam of the first effect of the evaporator cannot directly used as the self-effectiveness heat source, only can be used as the secondary or subsidiary effective heat sources. If it is used as the self-effectiveness heat source, additional energy must be supplied to it, so as to raise the temperature (pressure). The steam jet pump can only compression partial of the secondary steam, however MVR evaporator can compress all the secondary steam in the evaporator.

The solution is in an evaporation tank, and it can circulate in the heating pipe through the material circulation pump. Initial steam is heated from outside of the pipe via fresh steam; the solution is heated to be boiling to generate the secondary steam, which is sucked again by the steam compressor. After pressurization, the secondary steam’s temperature increases, and the steam is used as the heat source to enter the heat exchanger for circulation evaporation. After normal start up, the steam compressor inhales the secondary steam, which is pressurized and changed into heating steam, so circulation evaporation continuously go on. The evaporated moisture eventually become condensed water and then be discharged.

Main features of MVR evaporation system:

.Save energy consumption.

.In addition to preheating, the normal work needs no steam, to reduce environmental pressure.

.Need no cooling system, so that the cooling water can be saved.

.Compared with multi-effectiveness evaporation, it has features, such as simple process, compact equipment and small floor space.

.Compared with the traditional evaporation system, the heat exchange temperature difference is small, and the heat exchanging area is large.

.The product is evaporated mildly due to the low temperature difference designed for the system; therefore, concentrated liquid is not easy to occur high temperature metamorphism, coking and so on.

Main uses of MVR evaporation system:

- .Traditional Chinese medicine concentration (can be evaporated water, ethanol, methanol, etc.).

- .Sugar, milk, juice, beverage concentrate.

- .Salt wastewater concentration and crystallization (NaCl, Na2SO4, NH4Cl, etc.) salt crystallization.

- .Papermaking wastewater concentration.

- .Chemical wastewater treatment.

- .Distillation (can be used for distillation of ethanol, methanol, acetone, etc.)

- .Organic acid, chemical solvent distillation.

Working principle of MVR evaporation system refer to

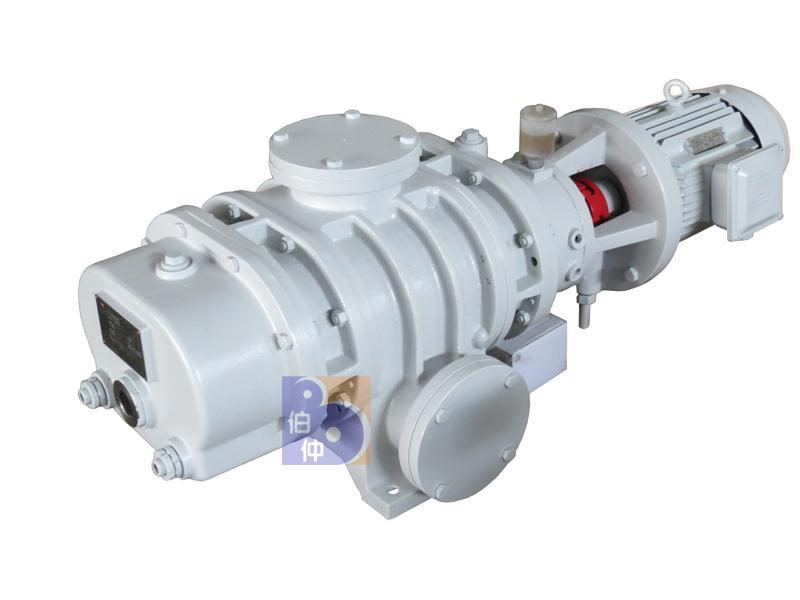

Main features of Roots series RVC type steam compressor:

Compressor model meaning:

R V C - 10 A - 22

R:Roots,Roots type

V:Vapor,Vapor

C:Compressor,Compressor

Maximum evaporation under low temperature conditions (kg/h, 10 C)

A: material code

22:power code, kW,kW

Relying on our company for many years the production of vacuum pump Roots experience, and combined with the requirements of MVR vapor compression, we developed a Roots series RVC type steam compressor, the main features are as follows:

- .Pump cavity is without oil, to avoid the oil vapor pollution evaporation system.

- .The vibration is small and the noise is small.

- .Mechanical friction loss is small, so the driving power is small.

- .Easy to maintain and repair, low cost, high life expectancy.

- .In order to improve the characteristics of the compressed water vapor and organic solvent, the emulsification of the oil in the bearing cavity and the corrosion of the pump cavity are solved.

- .Unique overheating eliminates design. By connecting the saturated steam return pipeline, so that roots compressor compressed heat is greatly reduced and the pump rotor cavity, pump body, end caps of temperature equilibrium, to avoid the due to impact by thermal expansion unevenness in the pump, pump seal burned, the pump was stuck phenomenon.

- .Because of our company's unique heat elimination design, no need to spray liquid from the pump to cool down, so as to avoid the liquid caused by the pump cavitation damage.

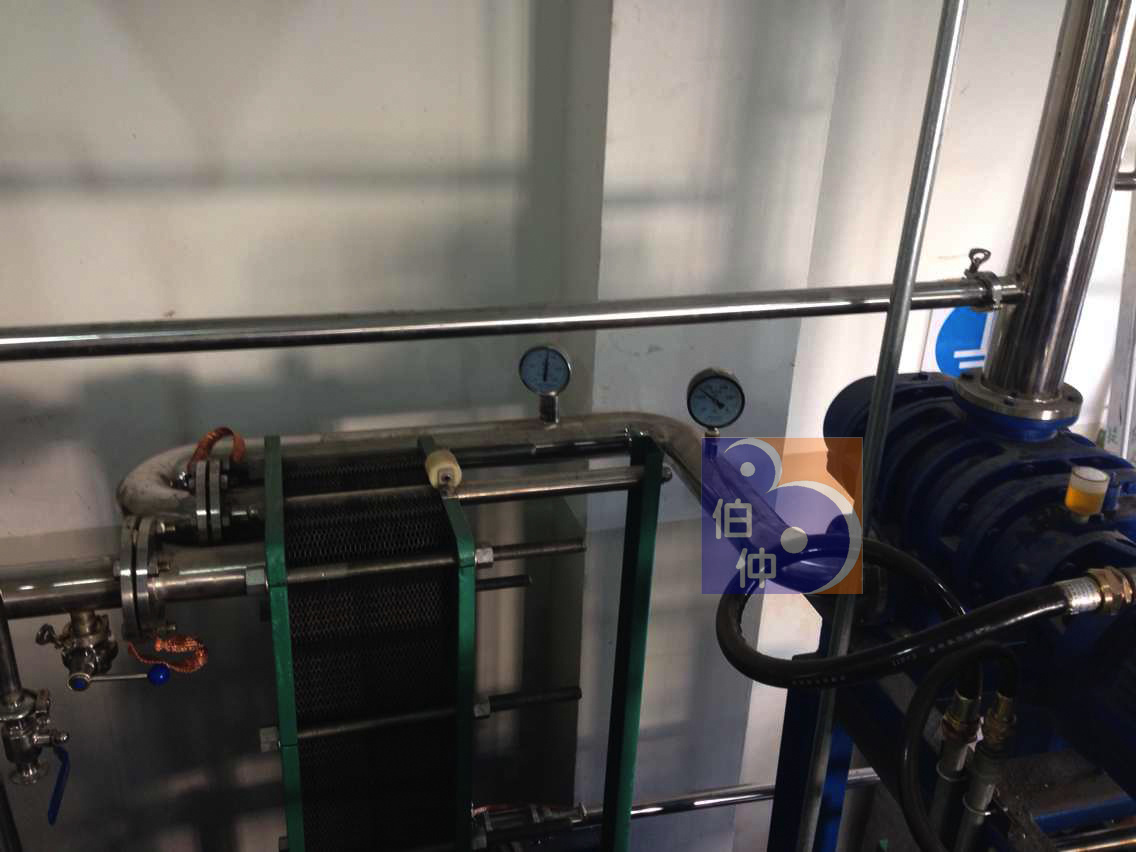

- .In order to improve the heat transfer coefficient of the heat exchanger, the heat transfer coefficient of the heat exchanger is improved by increasing the flow rate of the main heat exchanger by the flow rate of the flow.

- .In order to solve the special design of various solvents, the RVC Roots compressor is safe and efficient in the compression of various solvents.

- Its working principle may refer to Roots vacuum pump working principle

- Material selection of Roots compressor

-

Material code

A: rotor nodular cast iron NiP coating, pump body, end cap gray cast iron NiP coating

B: rotor ductile iron PFA 316L coating, pump body, end cap gray cast iron PFA 316L coating

C: C PFA HASTELLOY coating, pump body, end cover gray cast iron C PFA HASTELLOY coating

D:rotor, pump body, end cover SAF2205 dual phase stainless steel pump body

E: other materials

Accessories image area:

-

NiP coated rotor,NiP coated pump body and end cap,Hastelloy alloy + PFA coated rotor,Hastelloy alloy + PEA coating pump body,stainless steel rotor,stainless steel pump body

Roots compressor and centrifugal compressor are mainly used in MVR evaporation system. The main features are as follows:

|

|

Centrifugal compressor |

|

|

Compress feature |

The flow rate of Roots compressor is not sensitive to the pressure difference, which is a constant flow type compressor. |

Centrifugal compressor flow and pressure, compression ratio and so on has a great relationship, is a constant pressure type compressor |

|

Operating noise |

The operation noise of the medium. Roots compressor is related to the design of the compressor, the manufacturing precision of the equipment, the design of the pressure difference of the system and so on, because of its low speed, the operating noise is low frequency noise. |

Because the centrifugal compressor is a single axle design, the gear noise of the Roots compressor is reduced, because of its high speed, and the running noise is high frequency noise. |

|

Speed |

Lower. Generally 500~3000rpm |

Higher. Generally 10000~20000rpm |

|

Evaporation capacity |

Smaller. Generally 10kg/h~10000kg/h |

Larger. Generally 1000kg/h~50000kg/h |

|

Scope of work |

Because roots compressor compression ratio is very high, so even when MVR evaporation at very low temperatures can still obtain very high compression efficiency. Steam on operating temperature range for: 10 to 120 ℃. Roots compressor after optimization can be used for methanol, ethanol and other organic solvents MVR evaporation. |

Under the lower temperature of MVR evaporation compression efficiency is low, so can only be used in high temperature evaporation conditions. The general steam on operating temperature range: 60 to 120 ℃ centrifugal compressors of solvent MVR evaporation and application is still in the development stage. |

|

Running stability |

Because of the low speed, stable operation, no surge |

Because of high speed, high dynamic balance requirements, the need to avoid the surge during the operation. |

|

Security |

Due to the low speed, so it is safe to operate. In the compressed gas, the gas can be used in stainless steel and the way to increase the PTFE coating to eliminate internal security risks may arise. |

Due to the high speed, high speed operation of the impeller has a great centrifugal force, the strength of the parts of the impeller is very high; so that the safety of its operation is poor. |

|

Compressor efficiency |

Roots compressor, although parts more loss of some power, but because of its low speed, gas power loss is small, so the efficiency is high. The efficiency is 60~80% |

High speed centrifugal compressor caused a certain loss of power, its efficiency is generally 60~85% |

|

Seal features |

Due to low speed, the use of ordinary seals and mechanical seals to meet the requirements, long life, long replacement cycle, low maintenance costs. |

Special high speed seal, short life, short replacement cycle and high maintenance cost are required. |

|

Flow adjustment |

The flow of the compressor is proportional to the speed of the compressor, which can be easily controlled by controlling the speed of the evaporation. |

The flow rate is nonlinear, and it is difficult to control the evaporation. |

|

Over heat elimination |

Through the method of reflux cooling to eliminate the heat, no need to spray liquid from the entrance. |

Need to spray liquid from the compressor inlet to eliminate the compressed heat. |

|

Material selection |

Roots compressor can choose a variety of materials: A cast iron nickel plated B stainless steel C PTFE stainless steel |

Centrifugal compressor is generally stainless steel and titanium materials, etc. |

|

Maintenance and repair cost |

Pump oil, seals, bearings, etc. are ordinary parts, maintenance, low maintenance costs |

Seals, bearings and so on are special parts, maintenance, high maintenance costs |

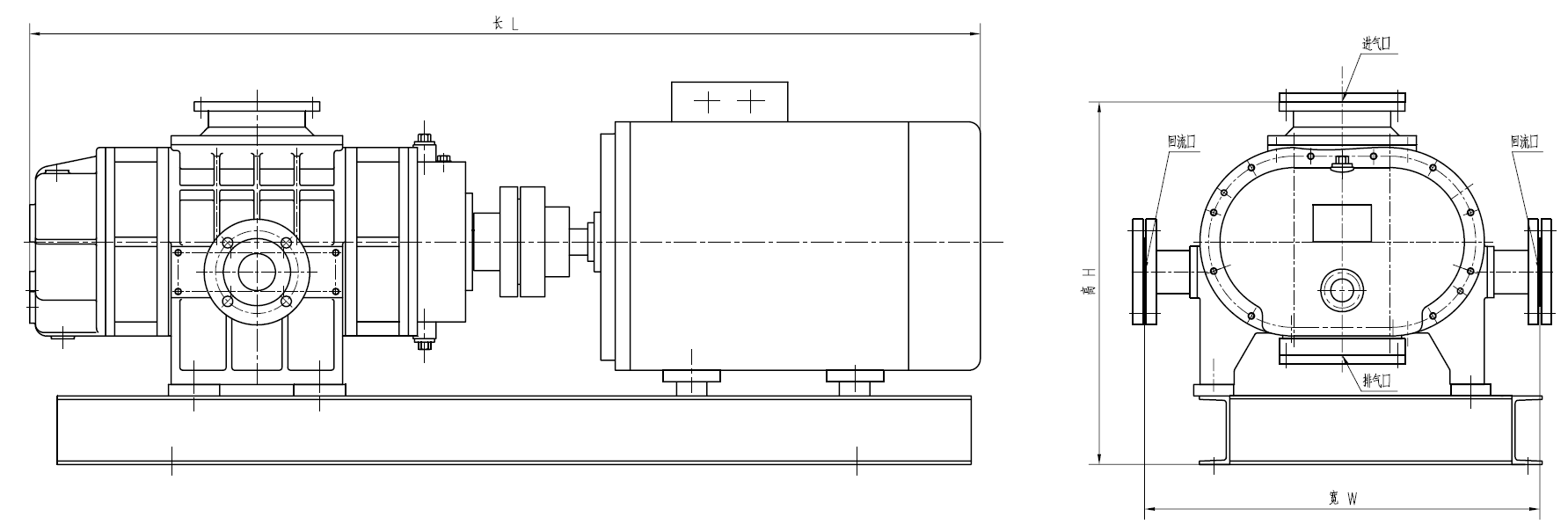

RVC Series Roots Steam Compressor Technical Parameter Specification

|

Model |

Flowrate m3/h |

Max. design pressure clearance kPa |

Speed r/min |

Inlet DN mm |

Outlet DN mm |

Return port DN mm |

|

RVC-1 |

5~100 |

80 |

150~3000 |

50 |

40 |

20 |

|

RVC-2 |

10~200 |

80 |

150~3000 |

80 |

50 |

25 |

|

RVC-5 |

25~500 |

60 |

150~3000 |

100 |

100 |

40 |

|

RVC-10 |

50~1000 |

50 |

150~3000 |

150 |

150 |

65 |

|

RVC-20 |

100~2000 |

50 |

150~3000 |

150 |

150 |

65 |

|

RVC-40 |

200~6000 |

40 |

150~2500 |

300 |

300 |

100 |

|

RVC-90 |

450~13000 |

40 |

150~2500 |

400 |

300 |

100 |

|

RVC-180 |

900~18000 |

30 |

100~1500 |

400 |

300 |

150 |

|

RVC-360 |

1800~36000 |

30 |

100~1500 |

500 |

400 |

200 |

|

Model |

Pump weight KG

(exclude motor) |

Motor power |

External dimensions(Max. power)

|

|

||

|

Length mm |

Width mm

|

Height mm

|

||||

|

RVC-1 |

70 |

1.1~5.5 |

880 |

380 |

220 |

|

|

RVC-2 |

90 |

1.5~11 |

1060 |

420 |

220 |

|

|

RVC-5 |

190 |

3~15 |

1350 |

500 |

380 |

|

|

RVC-10 |

450 |

4~30 |

1750 |

580 |

500 |

|

|

RVC-20 |

450 |

7.5~55 |

1870 |

580 |

500 |

|

|

RVC-40 |

1400 |

15~75 |

2220 |

1100 |

800 |

|

|

RVC-90 |

2100 |

22~132 |

2900 |

1100 |

800 |

|

|

RVC-180 |

3800 |

37~200 |

3000 |

1550 |

1200 |

|

|

RVC-360 |

5600 |

55~400 |

4200 |

1600 |

1300 |

|

Outline sketch map of Roots series RVC type steam compressor

MVR evaporation compressor type selection table (calculation in pure water)

Comparison of energy consumption of MVR evaporation system:

If the concentrated liquid has been pre heated, evaporation per1000kg water:

The use of a single-effect concentration needs consuming steam about 1200kg, the cost of about 240 yuan (cooling water consumption and pump vacuum, etc. are not included in the calculation).

The use of double-effect concentration needs consuming steam about 600kg, the cost of about 120 yuan (cooling water consumption and pump vacuum, etc. are not included in the calculation).

Triple-effect concentration needs consuming steam about 400kg, the cost of about 80 yuan (cooling water consumption and pump vacuum etc. are not included in the calculation)

MVR concentration does not need steam, only consuming power of 20~25 degrees, the cost is about 20 yuan, and does not require steam, cooling water and vacuum pump.

MVR system also applies to methanol, ethanol and other solvent evaporation process.

Common solvent MVR evaporation energy consumption (in addition to the special description, heat transfer temperature difference is calculated by 10 ℃):

Common solvent MVR evaporation energy consumption (in addition to the special description, heat transfer temperature difference is calculated by 10 ℃):

|

Evaporation medium |

Evaporation temperature |

Evaporation volume |

Power of MVR evaporation compressor |

Remarks |

|

pure water |

100℃ |

1000kg/h |

33.0kW |

If the temperature difference is 5℃, power consumption is 15.3kW |

|

Saturated NaCl salt water |

110℃ |

1000kg/h |

55.9kW |

The heat transfer temperature difference is calculated at 5℃ |

|

methanol |

65℃ |

1000kg/h |

18.8kW |

|

|

ethanol |

80℃ |

1000kg/h |

13.7kW |

|

|

acetone |

55℃ |

1000kg/h |

8.6kW |

|

|

dichloromethane |

40℃ |

1000kg/h |

5.8kW |

|

|

chloroform |

60℃ |

1000kg/h |

4.3kW |

|

|

toluene |

110℃ |

1000kg/h |

5.1kW |

|

|

Epoxy propane |

120℃ |

1000kg/h |

5.5kW |

|

|

ethyl acetate |

75℃ |

1000kg/h |

5.8kW |

|

|

acrylonitrile |

80℃ |

1000kg/h |

8.8kW |

|

|

Tetrahydrofuran |

65℃ |

1000kg/h |

7.1kW |

|

|

acetic acid |

120℃ |

1000kg/h |

8.7kW |

|

|

Meta xylene |

140℃ |

1000kg/h |

4.4kW |

|

Note:

1. In addition to the special explanation, the table data doesn't consider the impact of boiling point rising, such as the material is more complex or correlative data is uncertain; it is recommended to contact with my company for MVR evaporation tests to determine the key parameters.

2. If it needs to design a reasonable waste heat exchanger to recovering waste heat, the maintenance of the necessary steam (or other heat media) consumption is very little or needs no external heat source.

3. If it needs to design an external forced circulation pump, the power consumed is calculated additionally.

Sodium chloride wastewater MVR evaporation crystallization, different feeding concentration, energy consumption comparison of different processes:

(power kW, evaporation by 1000kg/h, evaporation temperature by 80℃, heat transferring temperature difference of 5℃; cycle pump and other power are not included)

|

Feeding concentration mass %) |

Single-stage evaporator Single-stage compressor |

Single-stage evaporator Double-stage compressor |

Double-stage evaporator Double-stage compressor |

|

0.2% |

45.4 |

34 |

17.4 |

|

0.5% |

45.4 |

34 |

18.7 |

|

1% |

45.4 |

34 |

21 |

|

2% |

45.4 |

34 |

23.3 |

|

3% |

45.4 |

34 |

25.9 |

|

5% |

45.4 |

34 |

27.2 |

|

7% |

45.4 |

34 |

29.5 |

|

10% |

45.4 |

34 |

31.6 |

|

15% |

45.4 |

34 |

33 |

|

20% |

45.4 |

34 |

34 |

|

30% |

45.4 |

34 |

34 |

When the high boiling point of the low concentration of material and ethanol, methanol and other MVR distillation conditions, the use of double stage evaporation plus of double-stage compression scheme is more energy saving.

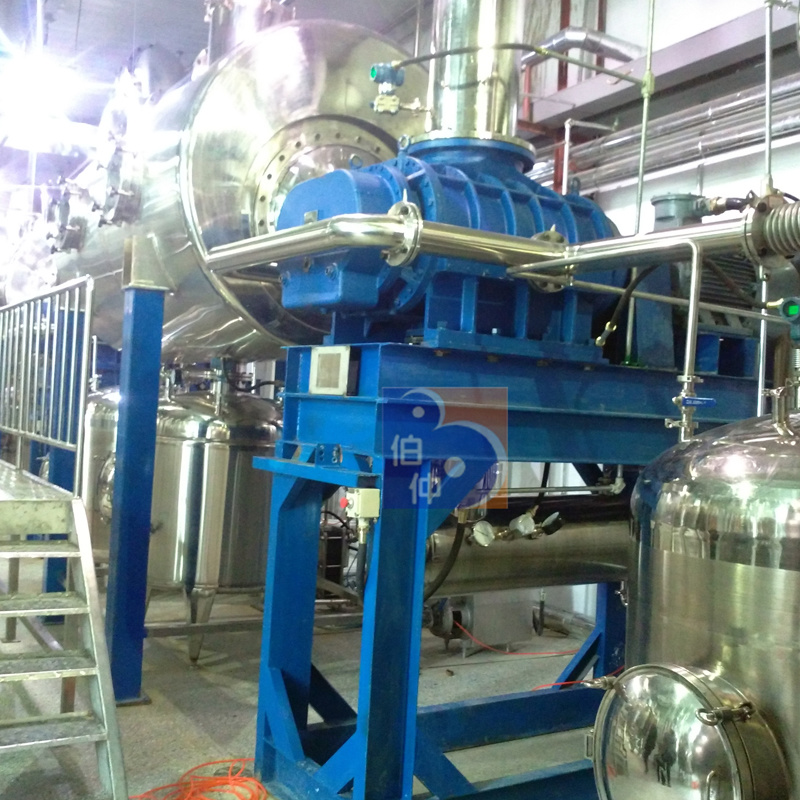

MVR equipment application::

Electroplating wastewater MVR treatment site Ethanol MVR evaporation site

Wastewater containing salt MVR treatment site Ethanol MVR evaporation site

Ethanol MVR evaporation site Ethanol MVR evaporation site

|

|

|

Processing equipment display::

Longmen processing center Five-axis machining center

Vertical machining center Roots compressor rotor machining

High precision dynamic balancing machine Surveying machines with three coordinates |