Products

Products

Contact Us

BoZhong (Shandong) Industrial Equipment Co., Ltd. | Part of the Atlas Copco Group

Address: No.50# YiDa Road, NanDing Town, Economic Development Zone, ZiBo, ShanDong, China

Tel: +86-533-2530388

Website: en.zbbz.com

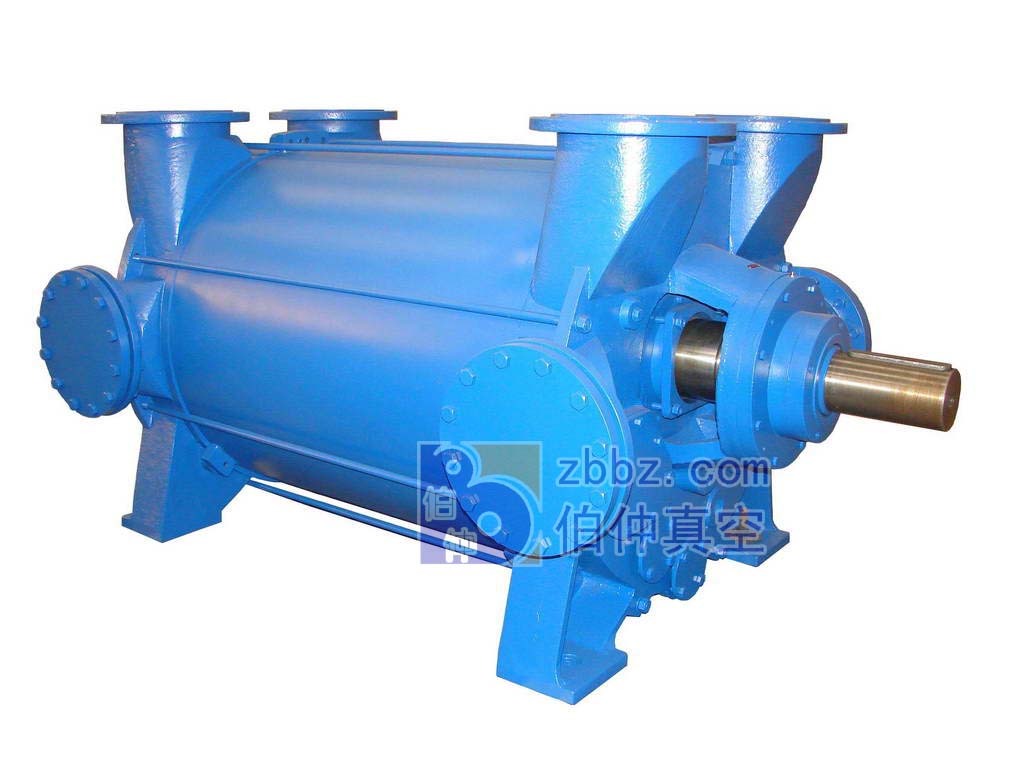

2BE3 series water ring vacuum pump and compressor

Uses and characteristics:

2BE3 series water ring vacuum pumps and compressors are designed and manufactured by our company integrating with the advanced technology abroad. They not only can save energy, but also can work constantly for a long time.

Under the rough vacuum situation, the requirements for the liquid ring vacuum pumps are very rigorous. So the 2BE3 series products are designed for pumping various gases. They are widely used in many industries, such as, the paper, mine, power station, chemical etc.

2BE3 series products can be driven with many different sets, such as, the V-belt, synchronic motor, gear box etc. In order to save space, more than two or at most four sets of the 2BE3 series pumps can be driven by one motor simultaneously.

When set a middle wall in the casing, the pressure tolerance between the two sides is lower than 80kPa and the two parts can work in different vacuum status respectively. Thus one pump can work well like two. Hereby the product operating flexibility is improved effectively

The main characteristics of 2BE3 series products:

.The tolerance, corrosive status, and the begrime situation can be easily observed by the big inspection port on both sides of the end-shield.

.The 2BE3 series pumps have flanges both on the top and sides with the same diameter. It is more convenient to connect with the 2BE3 series pumps.

.The bearings are all used of the imported products in order to keep the precise orientation and the high stability during the working of the pump.

.The material of the impeller is QT400 nodular iron or steel plates for ensuring the stability of the 2BE3 vacuum pump impeller under the various rigorous situations and extending the life of the pump effectively.

.The casing is made of steel or stainless steel plates to extend the lifetime of the 2BE3 series pumps.

.The shaft bushing is made of stainless steel plates to extend the life of the pumps 5 times more than the normal material.

.The V-belt pulley (when the pump is driven by the belt) is used of the high precise pulley with taper bushing to keep the reliability of the pump and extend its life. And it is also easy to mantle and dismantle.

.The unique design of setting the separator above the pump saves the space and decreases the noise efficiently.

.All the spare parts are cast by the resin sands that make the surface of the pump very smooth. So it is not necessary to cover the surface of the pump with putty and gives out the heat efficiently.

.The mechanical seals (optional) are all used the imported products so as to avoid the leakage during the working of the pump for a long time.

The photos of the spare parts:the welding impeller,the pump cover founded by the resin sand,the pump casing made of the curved steel board,port plate machined by the numerical control,shaft bushing made of Cr28 stainless steel,the corrosive-proof and wearable stuffing.

2BE3 series water ring vacuum pumps’ performance parameters

|

Model

|

Speed

(Drive type)

r/min

|

Shaft power

kW

|

Motor power

kW

|

Suction capacity

|

Limited vacuum

(Absolute pressure)

mbar

|

Pump head weight

(Contain the separator)

kg

|

|

|

m3/h

|

m3/min

|

||||||

|

|

340(V/reducer)

390(V/reducer)

440(V/reducer)

490(V/reducer)

530(V/reducer)

570(V/reducer)

610(V/reducer)

|

82

95 115 134 148 167 189 |

110

110 132 160 185 200 220 |

4850

5650 6250 6900 7470 8000 8600 |

80.8

94.2 104.2 115.0 124.5 133.3 143.3 |

160

|

3275

|

|

|

340(V/reducer)

390(V/reducer)

440(V/reducer)

490(V/reducer)

530(V/reducer)

570(V/reducer)

610(V/reducer)

|

108

132 157 180 204 229 260 |

132

160 185 200 220 250 315 |

6650

7650 8550 9400 10150 10700 11600 |

110.8

127.5 142.5 156.6 169.2 178.3 193.3 |

160

|

3720

|

|

|

260(reducer)

300(reducer)

340(reducer)

380(reducer)

420(reducer)

470(reducer)

|

142

171 203 238 277 338 |

160

200 250 280 315 400 |

8700

10150 11400 12700 13800 15500 |

145.0

169.2 190.0 211.7 230.0 258.3 |

160

|

6110

|

|

|

260(reducer)

300(reducer)

340(reducer)

380(reducer)

420(reducer)

470(reducer)

|

172

210 245 288 337 412 |

200

250 280 315 400 500 |

10700

12300 14000 15400 16800 18700 |

178.3

205.0 233.3 256.7 280.0 311.7 |

160

|

6740

|

|

|

230(reducer)

260(reducer)

290(reducer)

320(reducer)

350(reducer)

400(reducer)

|

205

243 285 322 365 465 |

250

280 315 355 450 560 |

12700

14400 16000 17500 19000 21600 |

211.7

240.0 266.7 291.7 316.7 360.0 |

160

|

9100

|

|

|

230(reducer)

260(reducer)

290(reducer)

320(reducer)

350(reducer)

400(reducer)

|

250

300 340 390 450 570 |

280

355 400 450 500 630 |

15600

17700 19500 21300 23200 26200 |

260.0

295.0 325.0 355.0 386.7 436.7 |

160

|

10700

|

|

|

210(reducer)

240(reducer)

270(reducer)

300(reducer)

320(reducer)

330(reducer)

370(reducer)

|

280

350 415 465 523 545 670 |

315

400 450 560 630 630 800 |

18300

20400 23160 25500 27000 27720 30960 |

305

340 386 425 450 462 516 |

160

|

12700

|

|

|

190(reducer)

210(reducer)

240(reducer)

270(reducer)

300(reducer)

340(reducer)

|

345

395 475 550 642 795 |

400

450 560 630 710 900 |

21900

24300 27480 30540 33780 38100 |

365

405 458 509 563 635 |

160

|

15700

|

|

Model \ suction pressure(mbar)

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

550

|

600

|

650

|

700

|

750

|

800

|

|

2BE3 400

|

9.5

|

9.9

|

9.9

|

9.5

|

9.0

|

8.7

|

7.9

|

7.5

|

6.6

|

6.0

|

5.3

|

4.7

|

4.2

|

|

2BE3 420

|

13.0

|

13.5

|

13.5

|

12.9

|

12.3

|

11.5

|

10.7

|

9.7

|

9.0

|

8.1

|

7.3

|

6.4

|

5.8

|

|

2BE3 500

|

17.6

|

18.3

|

18.3

|

17.2

|

16.6

|

15.4

|

14.4

|

13.2

|

12.1

|

11.0

|

9.9

|

8.9

|

7.8

|

|

2BE3 520

|

21.5

|

22.2

|

22.2

|

21.2

|

20.2

|

18.9

|

17.6

|

16.1

|

14.8

|

13.4

|

12.0

|

10.7

|

9.5

|

|

2BE3 600

|

24.6

|

25.4

|

25.4

|

24.2

|

23.0

|

21.5

|

20.1

|

18.4

|

16.9

|

15.3

|

13.7

|

12.2

|

10.9

|

|

2BE3 620

|

30.0

|

30.9

|

30.9

|

29.3

|

28.0

|

26.1

|

24.4

|

22.3

|

20.5

|

18.6

|

16.7

|

14.9

|

13.2

|

|

2BE3 670

|

34.6

|

35.5

|

36.4

|

34.6

|

33.0

|

30.7

|

28.7

|

26.3

|

24.1

|

21.8

|

19.7

|

17.6

|

15.5

|

|

2BE3 720

|

41.3

|

42.2

|

43.5

|

41.4

|

39.4

|

36.7

|

34.3

|

31.5

|

28.8

|

26.2

|

23.7

|

21.1

|

18.6

|